Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Company news

08

Nov

Why does the jaw crusher return material during the production process?

Returning is a common type of failure in the working process of the jaw crusher, this failure seriously affects the normal operation of the crusher when the crusher is working.In order to take targeted measures, it is necessary to fully understand the reasons for the crusher returning. Whether it can produce the returning phenomenon, it should be considered from the angle of the seesaw and the friction angle between the material and the raft.

1.In the processing and assembly of the crusher parts, some dimensions related to the angle, such as the length of the raft, the thickness, the length of the bracket and the angle of the bracket, the size of the cavity, etc.,which do not match the design dimensions of the drawings. However, when the friction angle is increased, it is possible to make the angle of the angle larger than 2 times, and the returning phenomenon occurs.

2.For the crusher of the same specification, the discharge opening is adjusted to different sizes, and the angle between the two jaws is also different.The smaller the width of the discharge port, the larger the friction angle, and the friction angle of the angle greater than 2 times may occur, resulting in a returning phenomenon.

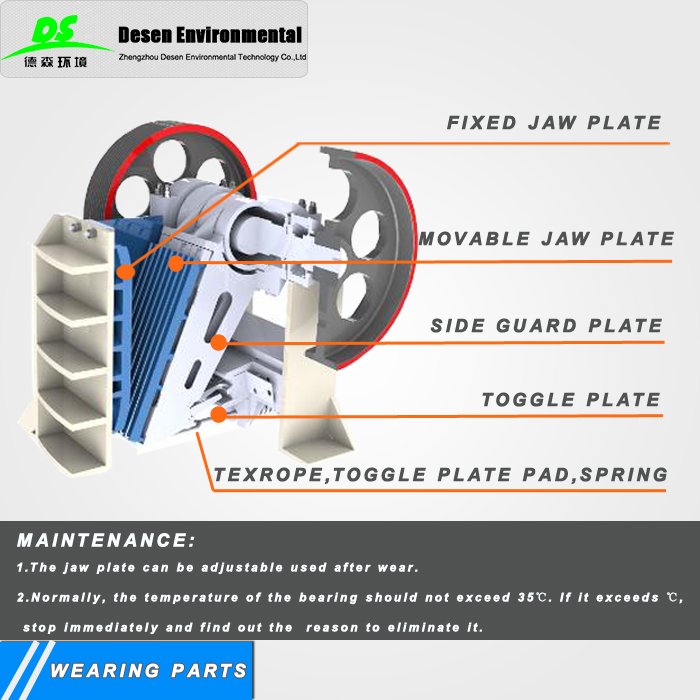

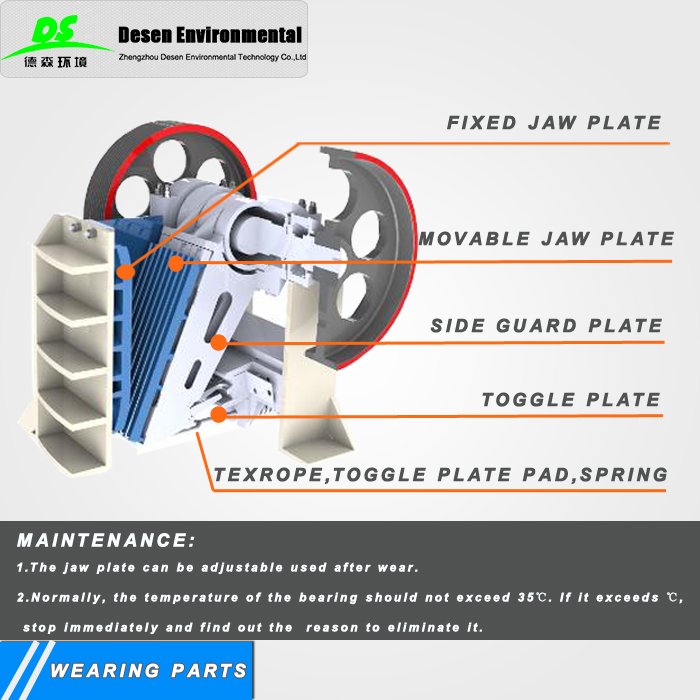

3.The cross section of the movable jaw and the fixed jaw of the jaw crusher are designed to have a tooth shape. The purpose is to increase the friction coefficient between the material and the jaw, and avoid returning.

4.When the particle size of the material to be broken by the crusher varies greatly, the condition of the friction angle of the jaw is less than 2 times, which is satisfied for the crusher.However, if a large piece of material is congested between two small pieces of material during work, the angle between the jaws will increase, and a friction angle of more than 2 times may occur, resulting in a returning phenomenon.

Leave a Comment