Feeding size:1100mm

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Feeding size:1100mm

Capacity:140-2000tph

Stone Hardness:≤150Mpa

Power: 90-600kw

Applied material: limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

{2else}

{2else}

{/pboot:2if}

{/pboot:2if}

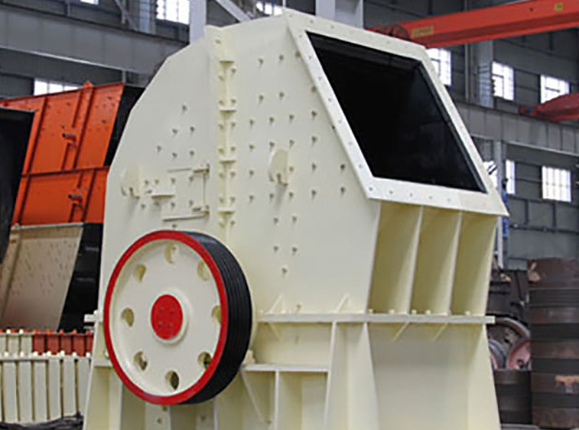

Heavy hammer crusher (hammer mill) are applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc.

The crushing compressive strength of materials should be not more than 150Mpa. Heavy hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials and compound fertilizer, etc.

And heavy hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure.

The advantages of heavy hammer crusher is have reliable mechanical structure, high productivity and favorable applicability

Hammer crusher hammer back with a tray mounted on a horizontal axis, mainly by the base, disc, cover, shaft, pin, hammer, bearings, discharge grate bar joists, eccentric suspension axis, spiral and other components.

Raw material is fed through the feeding mouth into crushing cavity, high-speed hammer violently shaken and thrown to the ladder arrangement liner, more violently crushed,crushing majority reached the desired size of the finished product that is calculated according to the unloading gap, The stone also impact with the hammer plate, they also impact each other.

So the crushing energy and place was being fully utilized. Single-directional rotating rotor hammer crusher multi-row structure.

All casing wall lined with manganese steel liner. Crusher rotor is keyed to the disc number only on the spindle formed.

The heavy hammer impact crusher was made up of crate, rotator, impact plate, hammer, gearing, etc. It is one new kind of crusher with hammer crusher and impact crusher’s advantages. And it is a very efficient, with advanced designing philosophy and technology. Compared to hammer crusher and impact crusher, the heavy hammer impact crusher’s advantages are as follows: high reduction ratio, epigranular, low energy consumption, high production capacity, etc. It can reduce the total equipment numbers by replacing the jaw crusher and impact crusher.

Available according to customer requirements, adjusting the size.

Working hammer, using new technology casting, with wear and impact resistance.

The overall design beautiful shape, compact structure, less wearing parts, easy maintenance, etc., is upgrading of products.

Compact structure, beautiful appearance, good wear resistance and easy mainten

| Type | Hardness | Capacity(T/h) | Input size(mm) | Rotating speed(r/min) | Power(kw) | Inlet size(mm) | Weight(kg) |

| ZC1212 | ≤150Mpa | 140 | ≤500 | 550 | 90kw-4 | 800-1200 | 7500 |

| ZC1414 | ≤150Mpa | 180 | ≤600 | 500 | 132kw-4 | 1000-1400 | 14000 |

| ZC1416 | ≤150Mpa | 200 | ≤600 | 500 | 155kw-6 | 1000-1600 | 17000 |

| ZC1616 | ≤150Mpa | 240 | ≤700 | 420 | 200kw-6 | 1200-1600 | 22000 |

| ZC1620 | ≤150Mpa | 320 | ≤700 | 420 | 200kw-6 | 1200-2000 | 28000 |

| ZC1820 | ≤150Mpa | 450 | ≤700 | 350 | 400kw-6 | 1600-2000 | 38000 |

| ZC2022 | ≤150Mpa | 550 | ≤1100 | 350 | 450kw-6 | 2000-2200 | 60000 |

| ZC2024 | ≤150Mpa | 650 | ≤1100 | 350 | 600kw-6 | 2000-2400 | 80000 |

| ZC2424 | ≤150Mpa | 1000 | ≤1100 | 300 | 500kw*2 | 2400-2400 | 120000 |

| ZC2626 | ≤150Mpa | 2000 | ≤1100 | 280 | 600kw*2 | 2600-2600 | 160000 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message