Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

News

15

Apr

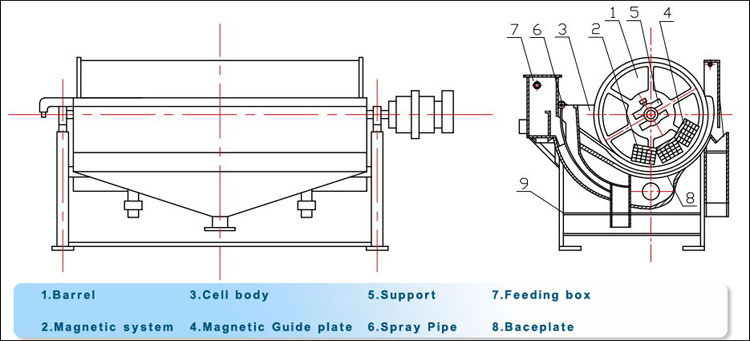

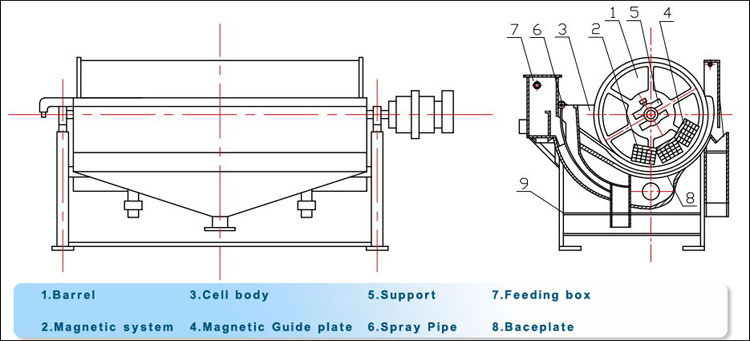

The Maintenance of Magnetic Separator

After using the magnetic separator for a period of time, it will inevitably lead to failure. At this time, it is necessary to stop the inspection and eliminate the fault. Zhengzhou Desen Environmental Technology Co., Ltd is a professional manufacturer of magnetic separators. The magnetic separator of the company is of excellent quality and reasonable price.

1.The drive chain wear is not allowed to exceed the regulations. If it affects normal use, it must be replaced resolutely.

Adjust the tightness of the drive chain in time.

2.For the proof drive sprocket, the linear deviation shall not exceed 1 mm. If there is deviation, it should be adjusted

in time.

3.Check and tighten the fixing bolts of the equipment support frame, motor, reducer and drum spindle.

4.The large end caps on both sides of the magnetic separator and the bolts on the bearing end caps are inspected and

tightened.

5.The body and the drum are thoroughly inspected for problems such as open welding, damage and deformation.

6.Measure and check the concentrate guide and the weir to maintain the level.

Leave a Comment