Feeding size: 20 mm

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Feeding size: 20 mm

Capacity: 0.5-25 tph

Fineness: 325-2500 mesh

Power: 150-590 kw

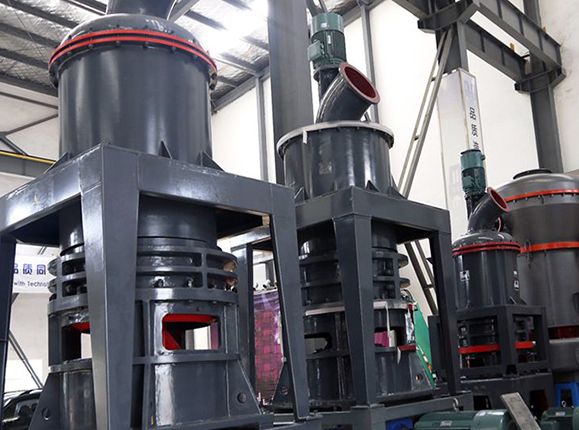

CXM series ultra-fine grinding mill is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials with Mohs's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite and other more than 200 kinds of stone materials.

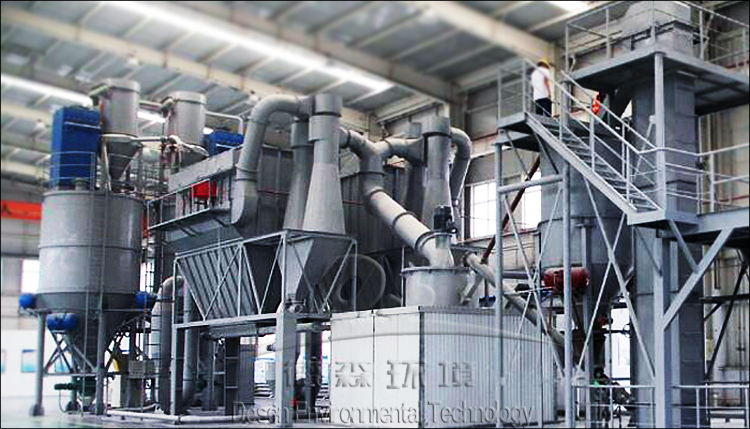

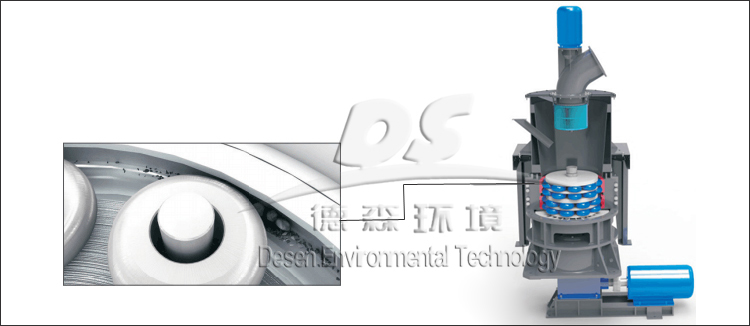

The ultra-fine grinding mill mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe. When the grinding mill is at work, the main bearing and each dial are driven by electromotor through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger. The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers. The high-pressure air blower constantly inhales air, airflow with crushed materials are brought to classifier whose high-speed impeller will screen the airflow: The unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; A small proportion of the fine powders, with airflow, moves to the dust cleaner. The materials from the above two lots are sent by the conveyor to get finished powders packed. In addition, filtered clean air will be emitted from muffler in the end.

High Efficiency:

Under the same finished final size and the same motor power, the capacity of ultrafine grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

Long life cycle of spare parts:

The ring and roller are forged by special steel material with high utilization, the lifetime can reach 2-5 years for grinding calcite carbonate.

High safety and reliability:

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

High fineness, flexible adjustment:

The final fineness of the grinding materials can be adjusted

| Model | CXM800 | CXM900 | CXM1000 | CXM1250 | CXM1680 |

| Ring diameter | 800 | 900 | 1000 | 1250 | 1680 |

| Ring number (pcs) | 3 | 3 | 4 | 4 | 4 |

| Roller number | 18-21 | 24-32 | 28-36 | 30-44 | 30-40 |

| Max feeding size (mm) | 10 | 10 | 15 | 15 | 20 |

| Fineness granularity (mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 |

| Capacity (kg/h) | 500-4500 | 800-6500 | 1000-8500 | 2500-14000 | 5000-25000 |

| Main motor power (kw) | 75 | 45*2 | 132 | 185 | 315 |

| Classifier motor power (kw) | 18.5 | 18.5 | 30 | 15*4 | 18.5*5 |

| Blower motor power (kw) | 45 | 55 | 75 | 110 | 90*2 |

| Elevator Model | TD-200 | TD-200 | TD-300 | TD-300 | TD-300 |

| Elevator motor power | 3 | 3 | 4 | 5.5 | 7.5 |

| Discharging screw conveyor | LS219*5 | LS219*6 | LS219*7 | LS219*5 | LS273*9 |

| Pulse bag filter | MCD120 | MCD160 | MCD250 | MCD450 | MCD400*2 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message