Max feeding size:750mm

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Max feeding size:750mm

Weight:2.8-8t

Power:3-22kw

Capacity:80-600tph

Applied material: limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

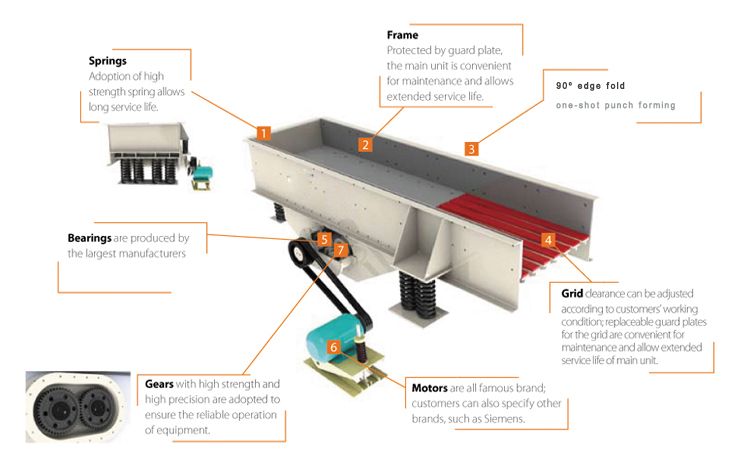

Vibrating feeder is mainly used for evenly conveying big size materials to the primary crusher. At the same time, utilize bars or mesh to screen the dirt or fine-grained material, realizing the purpose of advance screening. It is widely applied in metallurgy, mining, building material, silicate, aggregates, glass, cement, chemical and abrasive industries of crushing and screening combined operations etc. Desen gravel vibrating feeder could be designed particularly for continuous use with any hard and abrasive materials.

Vibrating feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to produce a linear huge power which forces the feeder to vibrate. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, avoiding the further crushing, so screening purpose can be reached.

Simple and advanced structure, evenly feeding, continuous performance, adjustable exciting force.

Easy to operate and change or control the flow at any time.

Low noise, small power consumption, good adjusting performance, and no missing phenomenon.

Adopt the closed structure can prevent dust pollution.

Stable vibration, reliable operation and long service life.

| Model | Max Feeding size (mm) | Capacity (t/h) | Motor Power (kw) | Through obliquity (degree) | Weight (kg) | Trough size (mm) | Dimensions (L*W*H) (mm) |

| GZD-650×2300 | 300 | 80 | 1.5*2 | 10 | 2798 | 650*2300 | 2300*1360*780 |

| GZD-750×2500 | 350 | 100 | 1.5*2 | 10 | 3260 | 750*2500 | 2500*1460*780 |

| GZD-850×3000 | 400 | 120 | 3*2 | 10 | 3607 | 850*3000 | 3110*1800*1600 |

| GZD-960×3800 | 500 | 96-160 | 5.5*2 | 5 | 4082 | 960*3800 | 3920*1640*1320 |

| GZD-1000×3600 | 500 | 150 | 5.5*2 | 5 | 3895 | 1000*3600 | 3850*1950*1630 |

| GZD-1100×4200 | 580 | 240 | 5.5*2 | 5 | 4170 | 1100*4200 | 4400*2050*1660 |

| GZD-1100×4900 | 580 | 280 | 7.5*2 | 5 | 4520 | 1100*4900 | 5200*2050*1700 |

| GZD-1300×4900 | 650 | 450 | 11*2 | 5 | 5200 | 1300*4900 | 5200*2350*1750 |

| GZD-1300×6000 | 750 | 400-560 | 11*2 | 5 | 7800 | 1300*6000 | 6082*2580*2083 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message