Feeding Size: <10 mm

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Feeding Size: <10 mm

Power: 5.5 -18.5 kw

Capacity: 20 -150 tph

Weight: 2.5-5 t

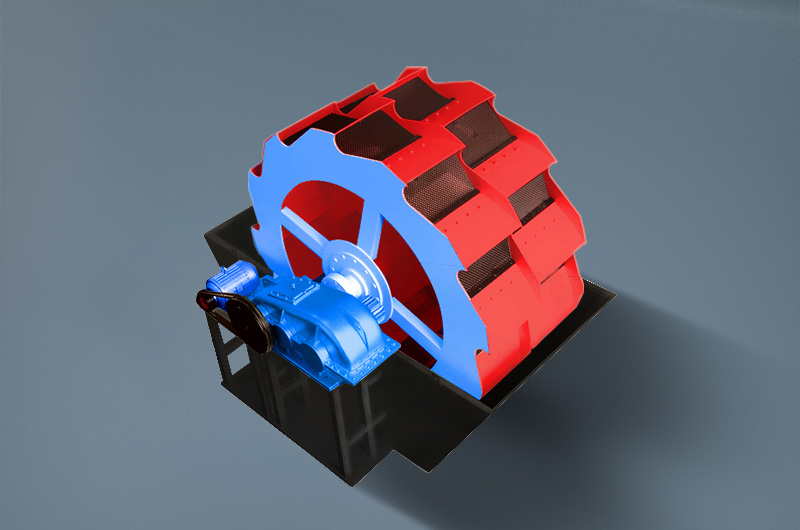

Sand washing machine, also called sand washer machine and silica sand washing machine, is a kind of washing equipment for artificial and natural sand. It is one of the major equipment of sand production line. The main task of this equipment in sand production line is to clean the crushed sand materials.

Simply put, Sand washing machine is used to remove the dust and stone powder in the sand produced by sand making machine, it also can do sand-selecting work or the similar process.

The machine aims at improve the quality and grade of the sand.

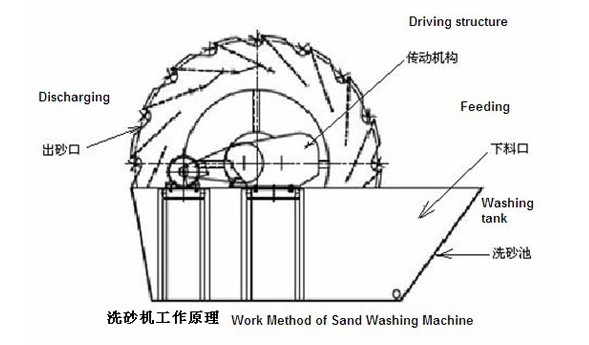

The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel.

The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away.

At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder.

Through the above process, the washing function is finished. The clean sand and stone is lift up by vane.

When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder.

On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used.

Finally, the sand and stone goes to the out launder from the rotary impellor to finish the washing task.

Minimal loss of fine sand and powder;

Large capacity, small power consumption;

Long life, easy maintenance;

Energy saving;

The machine is with high efficiency, reasonable structure, high capacity, low consumption and easy maintenance.

Drive Bearing device is separated from water and materials, which is greatly to avoid the bearing damaged due to soaking, touching sand and other pollutants.

Compared with the spiral sand washing machine, the loss of medium and fine sand as well as powder is minimal, so the grade and fineness modulus of washed building sand can meet the required standard.

Rational structure;

| Model | Impeller Size (mm) | Feeding Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimension (mm) |

| XSD2610 | ?2600×1000 | <10 | 20-50 | 5.5 | 2.68 | 3255×1982×2690 |

| XSD2816 | ?2800×1600 | <10 | 30-60 | 7.5-11 | 3.05 | 3540×3000×2880 |

| XSD3016 | ?3000×1600 | <10 | 50-120 | 11-15 | 3.26 | 3845×3000×3080 |

| XSD3620 | ?3600×2000 | <10 | 60-150 | 18.5 | 4.30 | 4500×3206×3480 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message