Spiral Diameter: 500-2400 mm

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Spiral Diameter: 500-2400 mm

Weight: 2-26 t

Capacity: 50-550 tph

Power: 3-40 kw

Applied material: limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

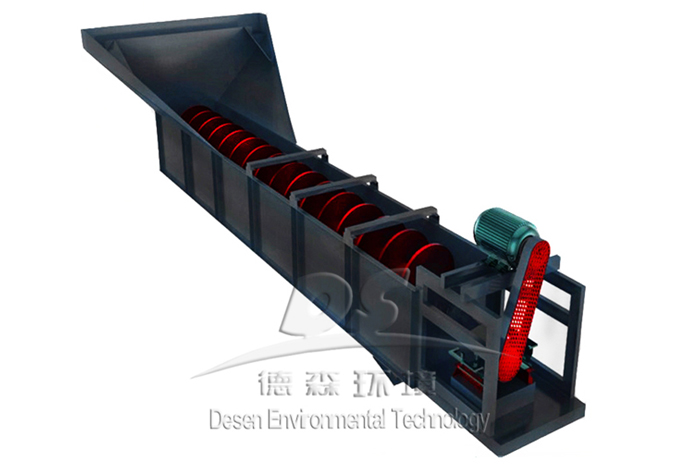

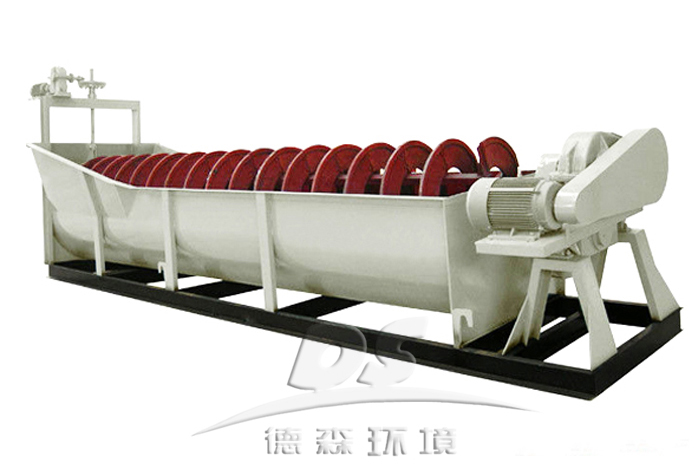

Spiral sand washing machine is suitable for construction sites, sand factory, hydro power station, concrete dam site, post and telegraph pole factory.

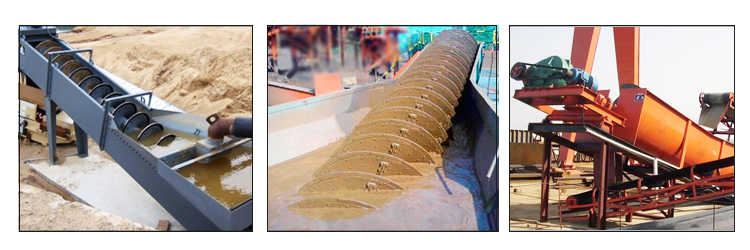

The required users’ sand and casting with "70" sand, glass quartz sand, oil filling pressure sand washing, grading and dehydration.

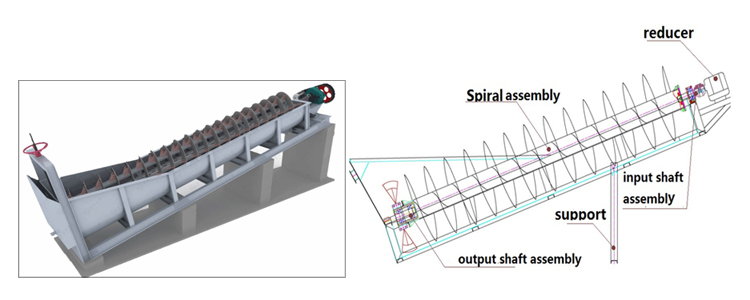

Sand washing machine according to 15° tilt arrangement, the lower of the water tank is composed of three side weir plates formed by sedimentation tank.

Screw head not into the settling tank, spiral by motor through reducer drive continuous rotation, clean water into the porous plate from the bottom of the tank.

This equipment has three functions: cleaning, dewatering, classify.

The material pours into the end of input,the spiral impeller ratates by the driven of the motor and the reducer, and then push the material inside the hopper close to the end of output. Thus, under the action of being advanced,mixed anf the flushing water, the mud wrapped on the material and the impurity go separately. Finally, the separated fine sands are discharged from the discharging port under the advancing movement of the spiral.Thus,the continous work of washing sand is finished again and again.Promptly carries off the impurity and the small proportion foreign matters,and discharge from the overflow port tank washer,completes the cleaning action.The clean sand and crushed stone is carried off by the leaf blade,and ids finally poured into the discharge chute from the revolving impeller,completes the cleaning action.

Spirochetes is long, good sealing system.

Simple structure, strong processing ability.

Sand withlow water content, low mud content.

Reasonable structure, convenient maintenance.

Model | Diameter of screw(mm) | Length of tub(mm) | Feed size(mm) | Capacity(T/H) | Speed of Screw(mm) | Electric motorpower(kw) | Waterconsumtion (T/H) | Weight(KG) | L*B*H(mm) |

XL915 | 915 | 7585 | ≤10 | 100 | 21 | 11 | 10-80 | 6271 | 8500*2810*3600 |

2XL915 | 915 | 7585 | ≤10 | 200 | 21 | 11*2 | 20-160 | 11110 | 8500*3765*3960 |

XL1115 | 1115 | 9782 | ≤10 | 175 | 17 | 15 | 20-150 | 10186 | 10970*3945*4720 |

2XL1115 | 1115 | 9782 | ≤10 | 350 | 17 | 15*2 | 40-300 | 17941 | 10970*5250*4720 |

XL1370 | 1370 | 10363 | ≤10 | 250 | 14 | 22 | 20-250 | 15349 | 11420*4458*5326 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message