Temperature:700-800°C

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Welcome to Jaw crusher | Ball mill | Rotary kiln | Raymond mill – Desen machinery !

Temperature:700-800°C

Power: 3-150 kw

Capacity: 1-150 tph

Weight: 3-190 t

Applied material: silica sand, river sand, fly ash, coal, quartz, gypsum, clay, carbonate calcium, limestone, etc.

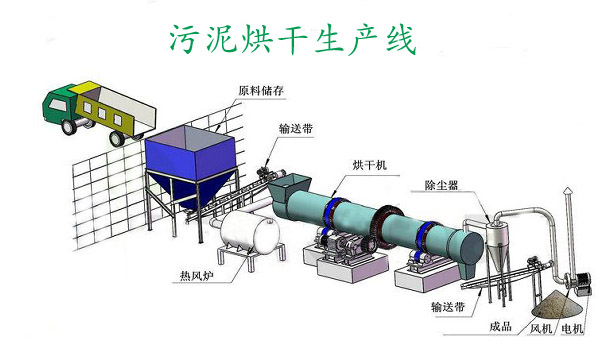

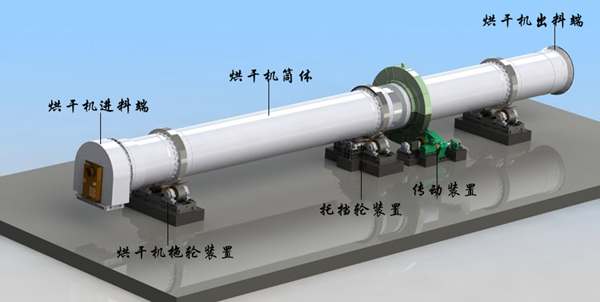

Rotary dryer is the most commonly used drying equipment among mining equipment, which is widely used to dry slag, limestone, coal, clay, grain, compound fertilizer, etc., in mining industry, metallurgy industry, chemical industry, building materials, compound fertilizer production and cement industry.

Rotary dryer has many names in the industry, which is often referred to as the rotary drum dryer and rotary dryer machine.

It is suitable for drying metallic and non-metallic minerals, the magnetic, heavy and floating concentrate, clay of cement industry as well as coal slime in coal industry.

Sand rotary dryer’s heat source is a combustion apparatus. It adopts direct flow heating with heat source from firing unit. The material to be dried is pushed back immediately by spiral board after going in the shell from feeding tank or feeding chute. Because the drier is installed in an inclined position, material flows to the back end under gravity and rotation force. At the same time, it is lifted by board repeatedly and thrown down accordingly, which makes the material form an even curtain, so that it can exchange heat sufficiently with the heat flow. At last, water in the material is dried by repeatedly scattering

High mechanization, big capability and continuous operation

Excellent and simple structure, steady operating process under resistance of the drum, easy operation

Little malfunction, low maintenance cost and power consumption

Wide application range and good drying effect.

| Model | Cylinder diameter (mm) | Cylinder length (mm) | Tilt Angle (°) | Cylinder speed (r/min) | Motor power (kw) | Dimension (L*W*H) (mm) | Weight (t) |

| HG-10×08 | 1.0 | 8 | 5 | 5.03 | 7.5 | 8000×2121×1910 | 12.2 |

| HG-10×14 | 1.0 | 14 | 5 | 5.03 | 7.5 | 14000×2121×1910 | 13.13 |

| HG-12×06 | 1.2 | 6 | 5 | 5.03 | 7.5 | 6000×2277×2320 | 9.38 |

| HG-12×08 | 1.2 | 8 | 5 | 5.03 | 7.5 | 8000×2277×2320 | 10.2 |

| HG- 12×12 | 1.2 | 12 | 5 | 5.03 | 7.5 | 12000×2277×2320 | 16.5 |

| HG-12×15 | 1.2 | 15 | 5 | 5.99 | 11 | 15000×2277×2320 | 17.94 |

| HG-15×12 | 1.5 | 12 | 5 | 4.02 | 15 | 12000×2835×2910 | 16.45 |

| HG-15×15 | 1.5 | 15 | 5 | 4.02 | 15 | 15000×2835×2910 | 23.1 |

| HG-18×12 | 1.8 | 12 | 5 | 4.59 | 18.5 | 12000×3330×3540 | 20.1 |

| HG-18×20 | 1.8 | 20 | 5 | 4.59 | 22 | 2000×3330×3540 | 34.5 |

| HG-20×14 | 2.0 | 14 | 5 | 4.59 | 1835 | 14000×3530×3740 | 31.68 |

| HG-22×16 | 2.2 | 16 | 5 | 4.59 | 22 | 16000×3645×3740 | 42.1 |

| HG-24×18 | 2.4 | 18 | 4 | 3.6 | 30 | 18000×3805×3965 | 48.66 |

| HG-24×22 | 2.4 | 22 | 4 | 3.12 | 37 | 2200×3965×3972 | 52.891 |

| HG-26×18 | 2.6 | 18 | 4 | 3.6 | 40 | 18000×4650×4660 | 65.75 |

| HG-28×14 | 2.8 | 14 | 4 | 3.12 | 40 | 14000×4650×4660 | 71.5 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

Note:Processing Capacity May Vary With Different Materisla Aan Feeding Sizes.

Zhengzhou Desen Environmental Technology Co.,Ltd, took through the ISO9001 quality system certification, CE certification, etc. And the products had continuously exported to more than 50 countries, such as Russia, Kazakhstan, Saudi Arabia, Iran, Egypt, South Africa, Vietnam, Indonesia, Mexico, Brazil, Peru and so on.

3800 People Use Desen Services

Leave a Message